Important Safety Information

Clydesdale can supply a range of Insulated Hand Tools designed, tested and approved / certified to Industry, National and European Standards. This range of tools offers 6 key safety characteristics;

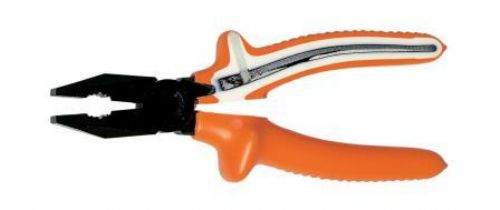

- A white shell is moulded onto the metal parts of the tool. This insulating shell is both unbreakable and irremovable, and ensures, instantaneously and permanently, total insulation of the tool.

- The orange coloured PVC which covers the shell coated tool is totally irremovable, non-flammable and ensures a perfect grip of the tool when held.

- Coating the handles with ridge marks ensures a perfect grip of the tool when held with greasy hands or gloves.

- The two finger stop (or Buffers) (where used) are made from treated Rilsan, which has insulation properties in excess of 15,000 Volts.

- The end of the handles are reinforced with several layers of PVC onto the shell, in order to withstand the highest of impacts.

- All insulating properties are guaranteed for temperatures from -20°C to +60°C (-4°F to 140°F).

The exceptional quality of this range of Insulated Tools ensures their use over many years.Every Insulated Tool within this range undergoes 7 separate tests prior to the end of the manufacturing process thus allowing us to offer a full guarantee on each and every tool. The range of Insulated Hand Tools complies with the current version of the following standards;

- EN 60900

- ESI 26-3

- VDE 0680

- NFC 18-400

Most important to European users is the EN 60900 Standard which gives the tool a rating of 1000V recognised by the double triangle symbol. The tool must pass the following rigourous requirements:

- Ambient Temp Impact Test - Tool must be dropped from a height of 2m and show no sign of break, tear or crack.

- Low Temp Impact Test - Tool is cooled to -25degC and must be dropped from 0.6m and show no sign of break, tear or crack.

- Dielectric Test - 10kV is applied between conductive and insulating components for 3min. Leakage current must be less tham 1mA per 200mm.

- Penetration Test - A weight of 20N is applied to the must vulnerable part of the tool while it is tested to 5kV for 3min. There must be no perforation or flashover.

- Insulation Adherence Test - At 70°C, a weight of 500N is applied for 3min to test the adherence of the insulation to conductive component. There must be no tearing or detachment greater than 3mm.

- Flame Propagation Test - The tool is exposed to flame for 10sec. The resulting flame should not exceed 120mm in the 20 second observation time.

- Individual Dielectric Testing - Each and every tool must be individually tested to 10kV for 10 sec without flashover and visually checked.